More than just a barrier

Quality protection. inspired design. unparalleled experience. exemplary service

Durable & Strong

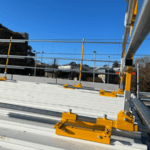

All our edge protection products have the ability to be adapted to suit the most complex of site access areas.

Comprehensive Solutions

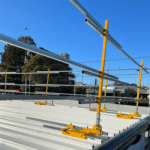

Comprehensive edge protection solutions for all timber, concrete & steel application types.

Cost Effective & Fast

All edge protection fixing components have been robustly designed with cost, speed and simplicity in mind.

Exceeding Standards

Designed to meet and exceed AS/NZS 4994.1:2009 conformity standards for temporary edge protection systems.

Australian Scaffolds has a big range of Edge & Roof Protection height safety products for sale.

We sell items such as L-Bends, handrail posts, couplers, brackets, guard rails and much more. All our height safety products are engineered and tested to ensure the highest quality standards are adhered to. We can supply all your Edge Protection needs for commercial or residential projects and we deliver Australia Wide. Designed to meet and exceed AS/NZS 4994.1:2009 the Australian / New Zealand conformity standard for temporary edge protection systems. All edge protection fixing components have been robustly designed with speed and simplicity in mind.

To speak directly with a qualified scaffolder for your scaffolding needs, call us today on 1300 919 905!

Australian Scaffold edge protection products are designed to suit all major brands of roofing including Longline, Custome Orb, Flatdeck, Spandek, Trimdek, Klip Lock and more.

Australian Scaffolds manufactures edge protection products in our Riverstone warehouse. Each product goes through a rigorous testing procedure to ensure our customers receive the best premium products available.

A CNC plasma cutter is a computer numerically controlled (CNC) machine that cuts through electrically conductive materials (such as steel, aluminium, brass and copper) by using a jet of hot plasma directed at the material to cut through it.

Australian Scaffolds plasma cutter is used to cut sheet metal into various shapes prior to bending, welding and galvanising processes are completed.

Manufacturing in-house gives Australian Scaffolds the technical knowledge to deliver better-designed products to our customers at a reduced cost.

General construction best practice and increasing regulations support the move away from ladders as a means of temporary access. As a result, adjustable stairs offer a simple, safe and practical solution for access between construction levels. Quickly and easily installed straight off the back of transport and ready for use in minutes.

The model WHS Regulations lists the scaffolding work that requires a high-risk work licence.

If you are carrying out scaffolding work where there is a risk of a person or object falling more than four metres, you must hold a scaffolding high-risk work licence. For example, if you erect a small frame to clean the eaves of a house or to paint a ceiling, and the distance you might fall is four metres or less, you don’t need a high-risk work licence. Above all, for more detailed information on setting up and operating scaffolds, see our General guide for scaffolds and scaffolding work.

What You Need to Know About Edge Protection

- access ladders are secured against movement

- where a platform is located more than 500 mm below the roof edge, then additional means of access to the roof is provided

- where an elevator, hoist or similar is used it is installed so that materials can be received at the roof level.

- toe boards or mesh in fill to prevent tools, materials or debris falling from the roof, unless a 2 metre ‘no go’ zone has been established to prevent persons entering the area below

- a clear gap between rails not exceeding 450 mm. The clear distance between a mid-rail and a toe board or bottom rail should not exceed 275 mm

- no gap between the roof edge, including the gutter, and a guardrail located outside the roof line exceeding 100 mm

- a clear distance between the roof cladding and the bottom rail of not less than 150 mm and not greater than 275 mm

- an effective guardrail height above the roof surface of not less than 900 mm (for roofs with a pitch over 10 degrees the effective height must be measured from a point 300 mm inside the roof edge)

- in fill panels where the pitch of the roof exceeds 26 degrees.

FAQ

Yes. We ship Australia-wide. If you want to confirm if we will be able to ship to you, please contact us to get a written quote. Click here to find out more about edge protection in Sydney, NSW.

Getting a quote for edge protection is very simple with Australian Scaffolds. Please fill out the detailed form in order to receive a quote from us. In addition to edge protection, we also provide access stairs, acrow props, rubbish chutes and more. We are Sydney’s trusted solution provider when it comes to scaffolding delivery as well as installation services.

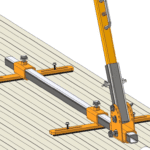

Figure 22: Guardrail system for roofing work

Extract taken from PREVENTING FALLS IN HOUSING CONSTRUCTION Code of Practice